Let your inspiration take over and guide you.

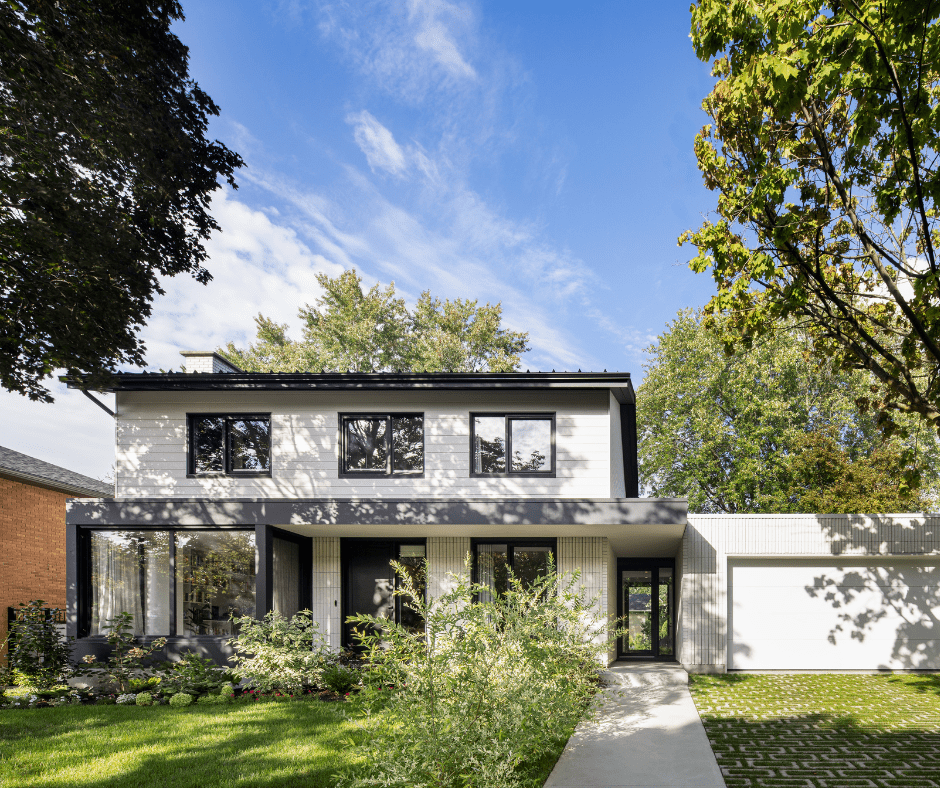

We offer door and window solutions with an impressive array of styles, colors and custom finishes. Our European door and window applications are uniquely custom made with materials exceptionally suited to our northern climate.

TOGETHER, LET'S CREATE SOMETHING INCREDIBLE.

Design

We believe that creating an idea is a process that reflects your creativity and your style. Our goal is to help you bring your most demanding architectural projects to life by offering you a personalized product adapted to your specific needs.

Installation

We will provide you with all the information and documentation necessary to ensure smooth installation of your Adurra windows and doors. Our goal is to ensure the proper functioning of the products by working closely with your contractor and architect

After-sales service

We never compromise our quality standards or our reputation. We believe that a superior product should be backed by an honest warranty, reliable after-sales service and expert customer support solutions, from design to installation.

We present to you a wide range of products with impeccable design and unwavering performances.

WINDOWS

Tilt-turn

Tilt-turn windows combines two opening mechanisms; tilting inwards from the top for ventilation and turning inwards for full access.

Tilt-turn

Architectural

Picture windows are primarily used to provide unobstructed views, enhance natural light and contribute to the overall aesthetics of your home's design.

Architectural

PATIO DOORS

Tilt-turn

Tilt-Turn balcony doors combine the functionality of a tilt-turn window with that of a door.

Tilt-turn

Lift & Slide

Lift & slide patio doors are designed to provide a seamless transition between interior and exterior spaces.

Lift & Slide

ENTRY DOORS

Essence

The Essence collection features fully customizable doors that come in various styles, from full glass to designs with smaller glass inserts.

Essence

Xclusive

The Xclusive collection features fully customizable full panel door models that can be tailored to fit your specific design preferences.